Engineering.

— We have customised our machines with in-house technology to improve track resurfacing and make Australian railways safer, smarter and more efficient.

Whether you need a dynamic machine that can do it all quickly or a specialised machine on a long-term project, we have tailored our fleet to complete any job in Australian rail maintenance to the highest standard.

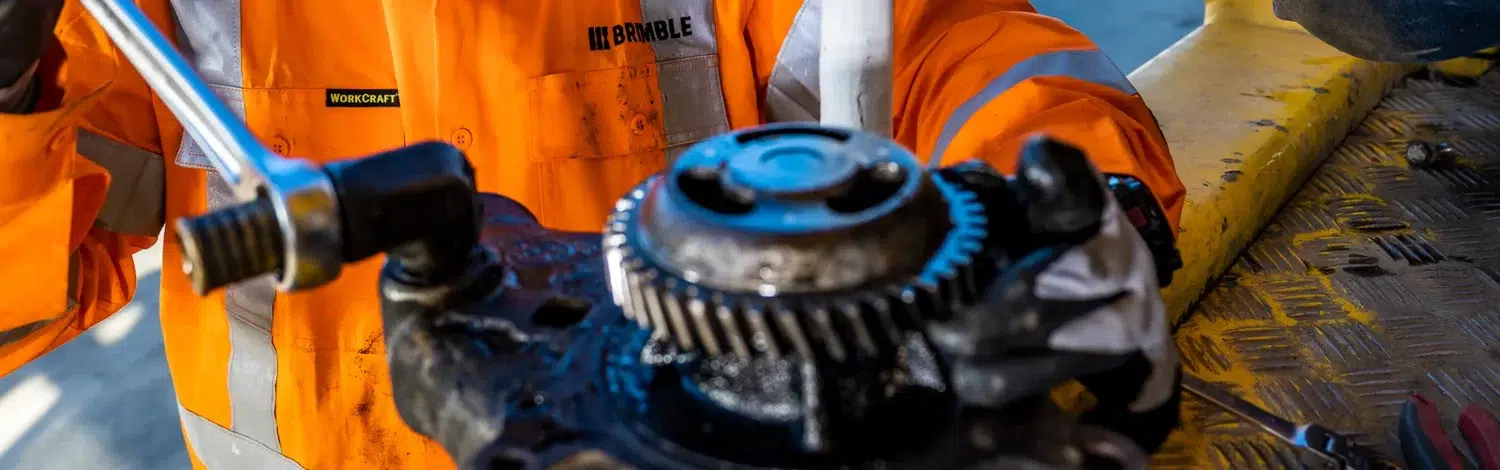

Track Machine Maintenance

Servicing, support and repairs of rollingstock.

- Track Machine Servicing according to Technical Maintenance Plan (TMP)

- Breakdown Response & Support

- Machine Repairs

Track Machine Upgrades

From small-scale modifications to complete control system upgrades.

- Interface Upgrades

- Dynamic Modifications

- Structural Modifications

- Component Engineering

- Decarbonisation

Track Machine Rollingstock Compliance

We ensure our rollingstock meets all technical standards.

- Static Assessments

- Dynamic Assessments

HMI Technology

In response to the historically complex and inconsistent technology used in track resurfacing, we developed our HMI system (human machine interface) to not only create efficiencies, but prevent accidents and injuries on the job.

Delivering safer, smarter and more efficient railways

We’ve had three generations in rail to hone our technology and methods. We pass those benefits onto our clients with railways that truly perform.